NORD FLEXBLOC® Ordering Guide

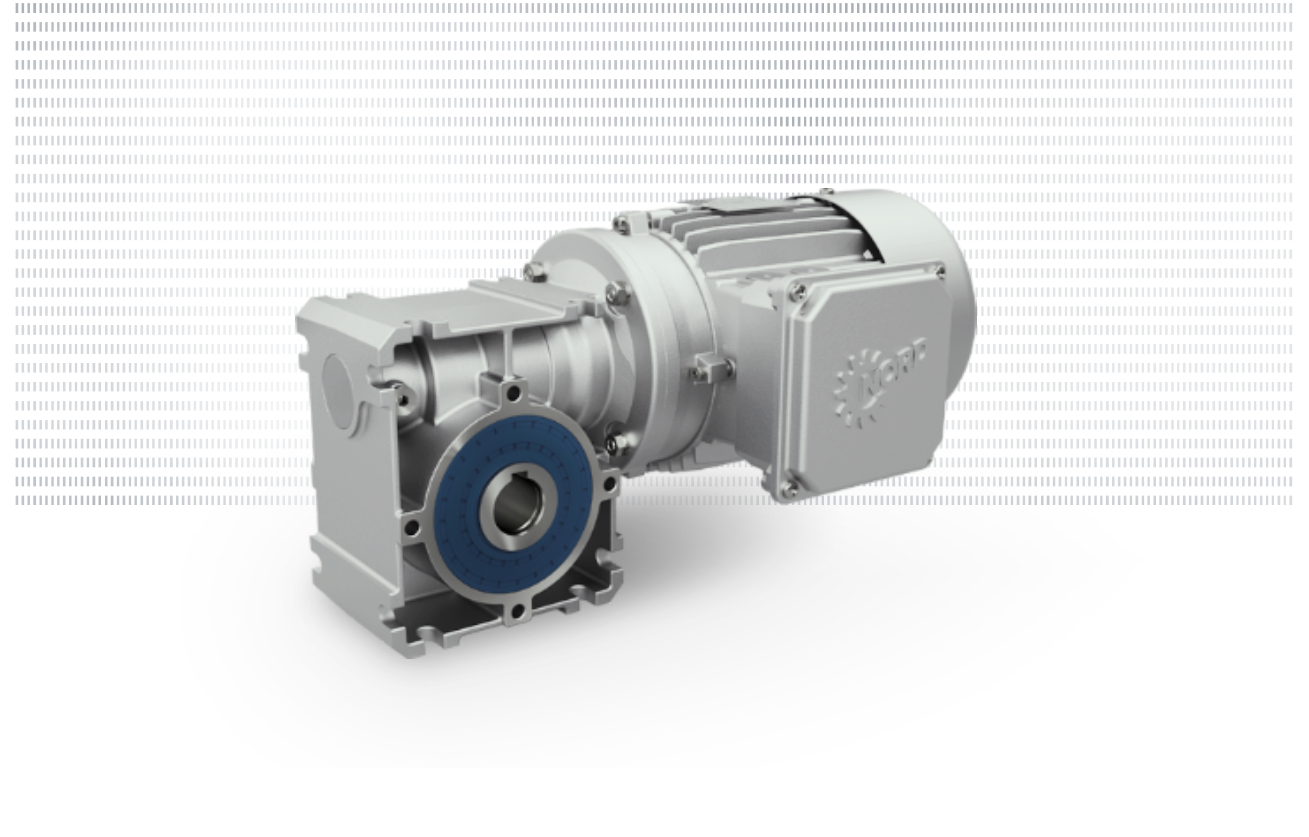

FLEXBLOC® Worm Gear Speed Reducers from NORD Drivesystems are one of the most popular items that we sell, mostly due to their low cost and modularity. The bolt-on motor flange adapters and accessories make it much easier for us to carry the majority of possible configurations in stock.

The FLEXBLOC® series of Gearboxes, Electric Motors and Accessories are meant to be ordered as component parts and are very simple to assemble yourself. For that reason, we have developed this guide to explain how to select all the proper components you will need to build the correct gearmotor for your application.

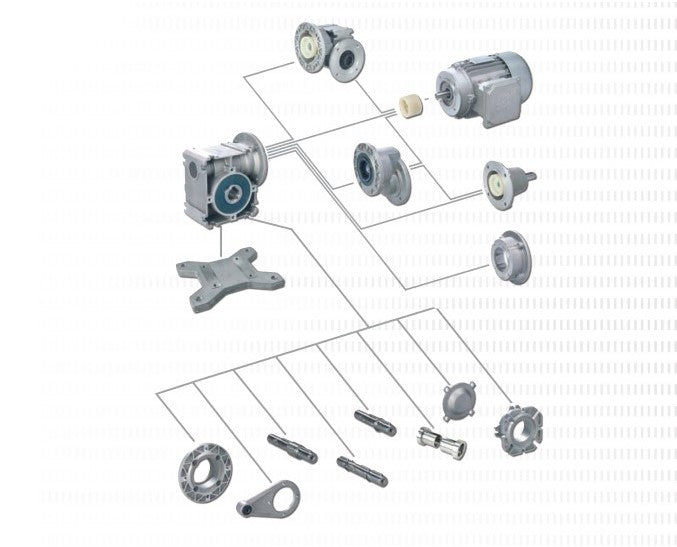

There are 3 main components required to assemble a basic FLEXBLOC® gearmotor.

There are also many other optional accessories available.

Step 1: Select your Speed Reducer

The main things you need to determine are center distance and gear ratio.

First, select your desired output speed in rpms, then divide 1750 by that number to get your gear ratio. Example: you want an output speed of 90 rpms; 1750/90=19.44, so you would select a 20:1 gear ratio.

Then, determine the required torque to move your load (this can be a little more complicated, give us a call if you need some assistance). Using the FLEXBLOC Ratings Chart, follow the left-most column down to your gear ratio, then in the "1750 input rpm" row of that section (assuming you are using a 1750 rpm motor) follow it to the right until you find a "Torque [lb-in]" that is greater than your required torque. Example continued: your application requires 1000 lb-in of torque to move the load; follow the left column down to "20" total ratio, then follow the 1750 row over to the "torque" column for each reducer, SK1SI31= 239 lb-in, SK1SI40= 398 lb-in, SK1SI50= 717 lb-in, SK1SI63= 1274 lb-in, SK1SI75= 2036 lb-in. So, you should select SK1SI63 (63mm center distance) because it is the smallest reducer that exceeds your torque requirement.

Another consideration is your shaft size. In our example, the SK1SI63 comes with either a 1-7/16" or 25mm hollow shaft. If you would like to use a different sized shaft, you can use a Reducer Bushing, or if you are driving with a sprocket or pulley, you can use a Plug-In Shaft.

Step 2: Select your Electric Motor

The next step is to select your electric motor. You want to make sure that your horsepower does not exceed what your speed reducer is capable of. Using the FLEXBLOC Ratings Chart mentioned above, you can also find the maximum input horsepower, this is also listed in the specifications tab on the product page of each speed reducer. For example, the SK1SI63-20:1 reducer has a maximum input horsepower of 2.22, so you would want to choose a 90LP/4 (2HP) or smaller. Keep in mind that the output torque will be diminished from what is shown in the ratings table by the difference between the maximum input vs the selected horsepower. For example, the SK1SI63-20:1 shows an output torque of 1274 lb-in, but that is at 2.22HP, which is not an actual motor horsepower. So, if you are using a 2HP motor, your output torque will actually be 1148 lb-in (2/2.22=0.9*1274=1148).

Step 3: Select Your Motor Adapter

Once you have selected your speed reducer and your electric motor, now you need to select the motor adapter that will connect them together. The easiest way is to go to our Motor Adapter page, select the center distance of your speed reducer (SK1SI31= 31mm, SK1SI40= 40mm, etc.) and the flange size of the electric motor you selected (this can be found in the product description, ex; 71L/4-B14 C105 has a B14 C105 flange and a 71L/4-56C has a 56C flange). With the NEMA motors (56C, 140TC, 180TC), only the first 2 digits of the flange size are critical. If the motor shows a 143TC frame size, you would select the 140TC motor adapter.

Step 4: Select Any Additional Accessories

NORD offers a large selection of accessories for their FLEXBLOC® Gearmotors, and we carry most of them in stock.

Mounting Foot Plates mount to the bottom of the speed reducer to provide drop-in compatibility with many other brands of worm gear reducers.

Breather Vents regulate the internal pressure of the speed reducer and keep contaminants out.

Double Worm Gear Adapters are used to create double reduction gear reducers. They mount the output of an SK1SI31 (or SK1SI40) to the input of the larger SK1SI40/50/63 (or SK1SI75). This can be used to create up to a 3000:1 gear ratio. To calculate your final gear ratio, multiply the ratio of each reducer together. For example, a SK1SI31-30:1 mounted on a SK1SI63-30:1 would create a final 900:1 ratio.

Output Flanges mount around the output of the speed reducer and are used to bolt the reducer to the machine. There are multiple sized flanges available for each size gearbox.

Plug-In Shafts are inserted into the hollow bore of the gearbox with a key and are retained in place with an external snap ring. This will give you a solid output shaft that you can mount a pulley, sheave or sprocket onto.

Reducer Bushings are inserted into the hollow bore of the gearbox from both sides with a step key in between, and are used to adapt to various shaft sizes for greater bore flexibility. If you don't find a reducer with the correct hollow bore size, choose one with a larger size, and use a reducer bushing. Don't see the size you need? We can have them custom made to fit on your shaft, just give us a call or shoot us an email.

Shaft Covers seal the shaft end opposite your drive side for safety/protection from the rotating shaft. Simply bolt the cover on using the 4 holes around the hollow output bore seal.

Solid Input Shafts bolt onto the input of the gear reducer and provide a solid shaft extension for using a sprocket, pulley or sheave to power your speed reducer. Only available for sizes SK1SI40/50/63/75.

Torque Arms are used to hold the gearbox in place when driving a shaft, it will prevent the reducer from rotating around the shaft. It bolts around the output of the gear reducer and has a rubber shock absorber installed in the attachment end for vibration dampening.

As you may have gathered, selecting the perfect gearmotor for your application can be a daunting task, but NORD has made it much easier with the modularity of the FLEXBLOC® series. Whether you are looking for a replacement or a new application, Power Motion & Industrial Supplies is here to help. With such a wide range of possible configurations available, it is essential to work with a knowledgeable distributor like us to configure the perfect gearmotor for your application. We encourage you to contact us for any assistance, and we look forward to helping you find the perfect gearmotor!

Leave a comment